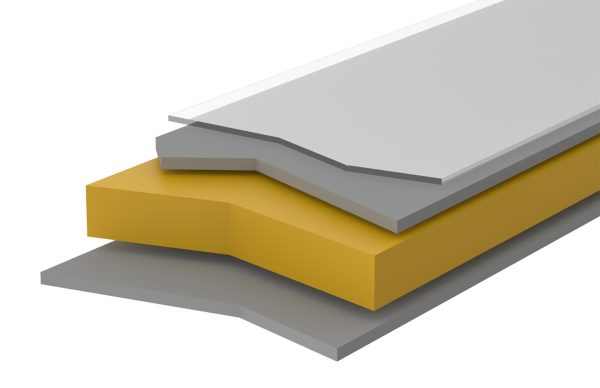

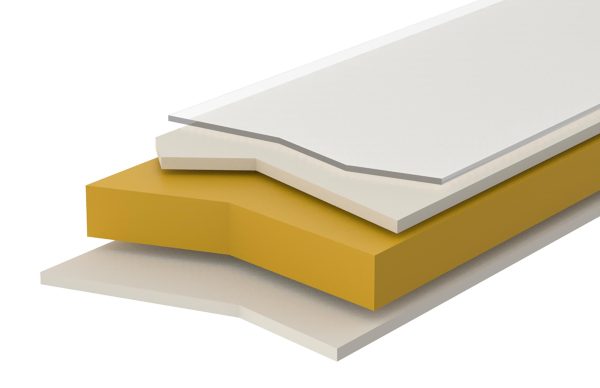

The panel with antibacterial PVC film coating is composed of:

Maximum antibacterial property classification, with more than 99% bacterial reduction capacity.

Proven efficacy with the following bacteria:

Antibacterial PVC can be used in a wide range of applications:

The surface needs some essential care when it comes to cleaning:

Varnish retouching on surfaces with this coating: